Multi-capillaries

The cross-sections of these capillaries comprise a variety of individual openings, which are either randomly arranged or form a (strictly) arranged structure. With anything from 2 to 500 channels, the capillaries can be used for a wide variety of tasks.

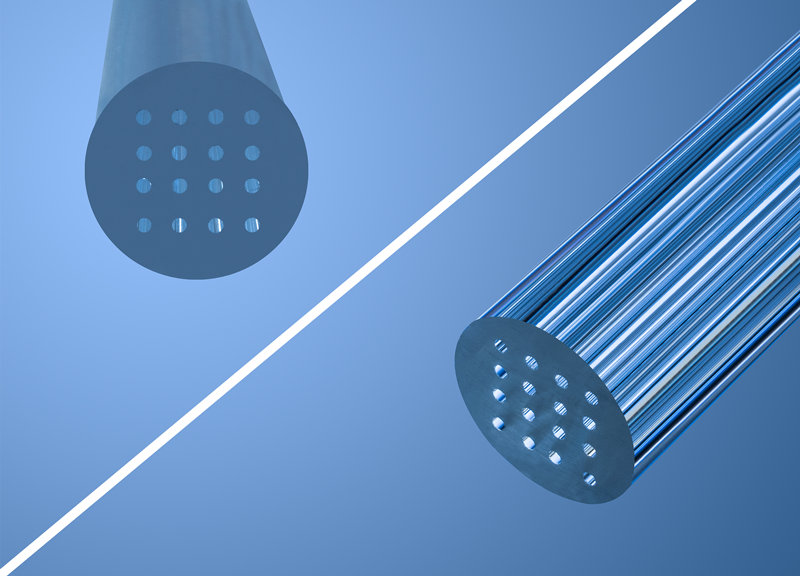

Our multi-capillaries are divided into two categories: those manufactured from a single piece and those comprising individual capillaries where the gaps are filled. There are two approaches taken here:

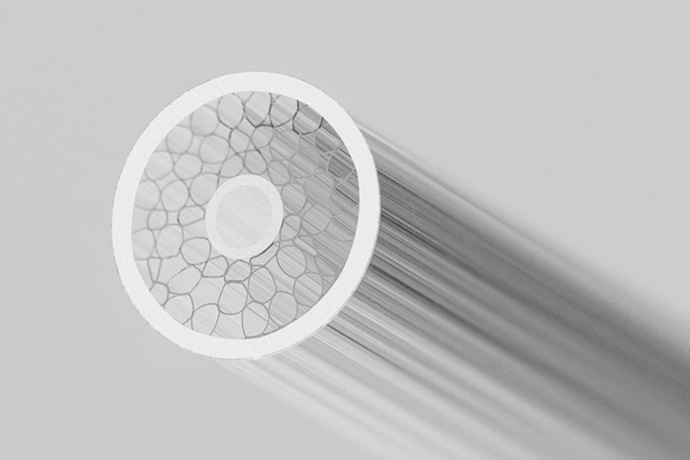

1. Manufactured from a preform

Before the process of drawing (and stretching) the capillaries, corresponding preforms are assembled and joined together. Here, the channels are created by the individual capillaries. The resulting hollow spaces are filled with glass rods and then evacuated with heat. This causes all unwanted side channels and hollow spaces to close up, with the result being a closed cross-section only punctuated with the internal geometry of the individual capillaries. When using thick-walled capillaries, easily reproducible cross-section sizes are possible. The closed area is proportionately larger than the open space of the holes. Thin-walled capillaries create a very airy structure with fewer closed spaces and a large open cross-section. Due to their thin walls, these capillaries tend to be easier to deform on the inside and are therefore not entirely suitable for the manufacture of precise internal geometries.

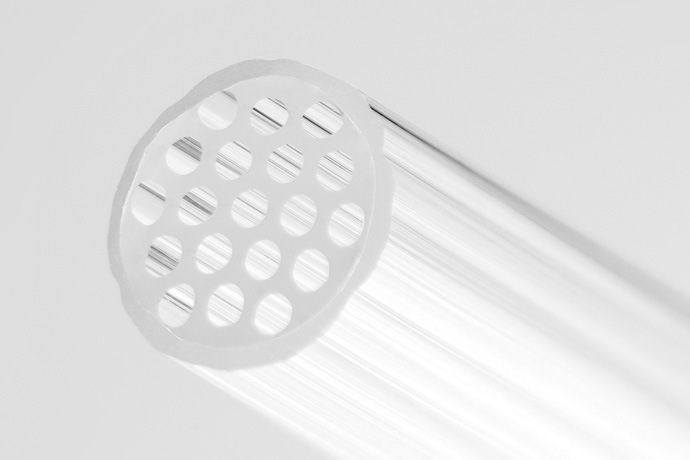

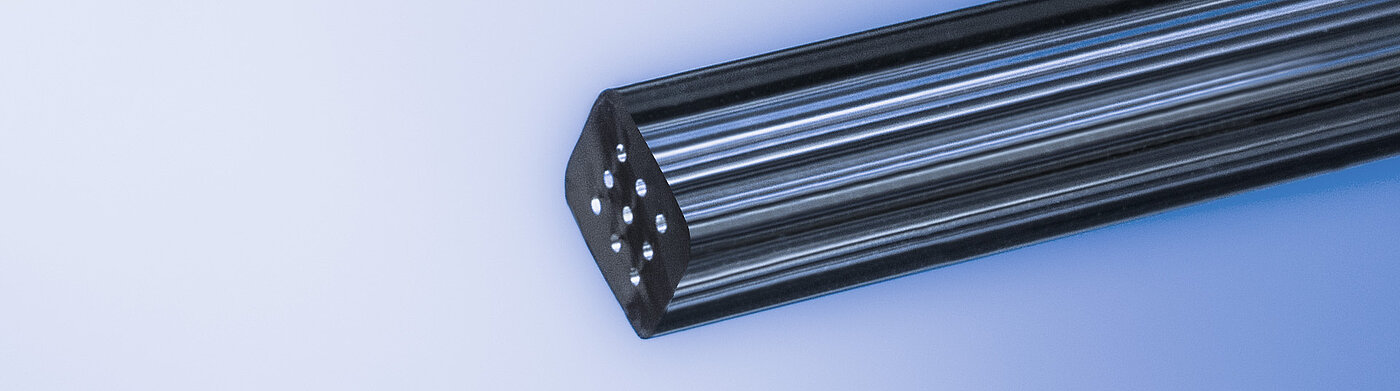

2. Manufactured by laminating with epoxy resin

Another approach to the manufacture of multi-channel capillaries involves lamination with epoxy resin. This method is particularly suitable when ambient parameters, such as high temperatures or solvent resistance, do not explicitly require a pure glass structure, however the accuracy of the internal diameter is important. Here, correspondingly high-precision single capillaries are added to an array or bundle. The hollow spaces between the capillaries are sealed with an acrylate- or epoxy-based resin and cured with UV light. Depending on the application, there are a variety of adhesives to choose from.

Square capillaries with 9 inner channels

In addition to the ninefold bundle capillaries, we have created a new multi-channel capillary containing 9 small, symmetrically arranged channels in a square cross-section. The channels here are all the same size and the outer edges of the capillaries are rounded. The capillaries are used in the manufacture of sensors, electrophysiology and analytics.

SPECIAL

We have already manufactured special customer-specific solutions for this product group. Further examples of special products can be found under the respective product category or under Special Solutions.

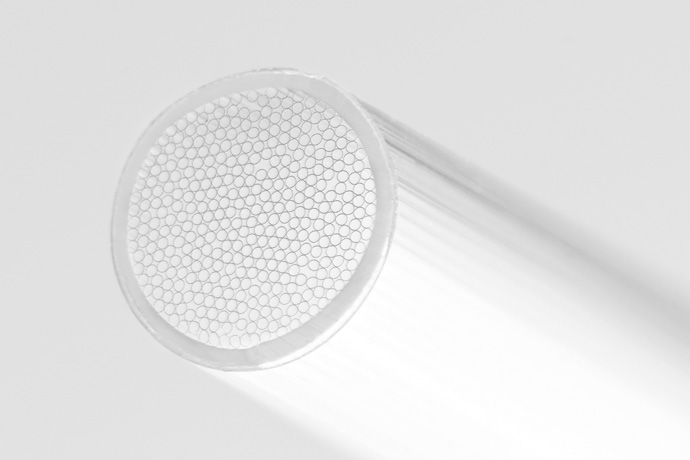

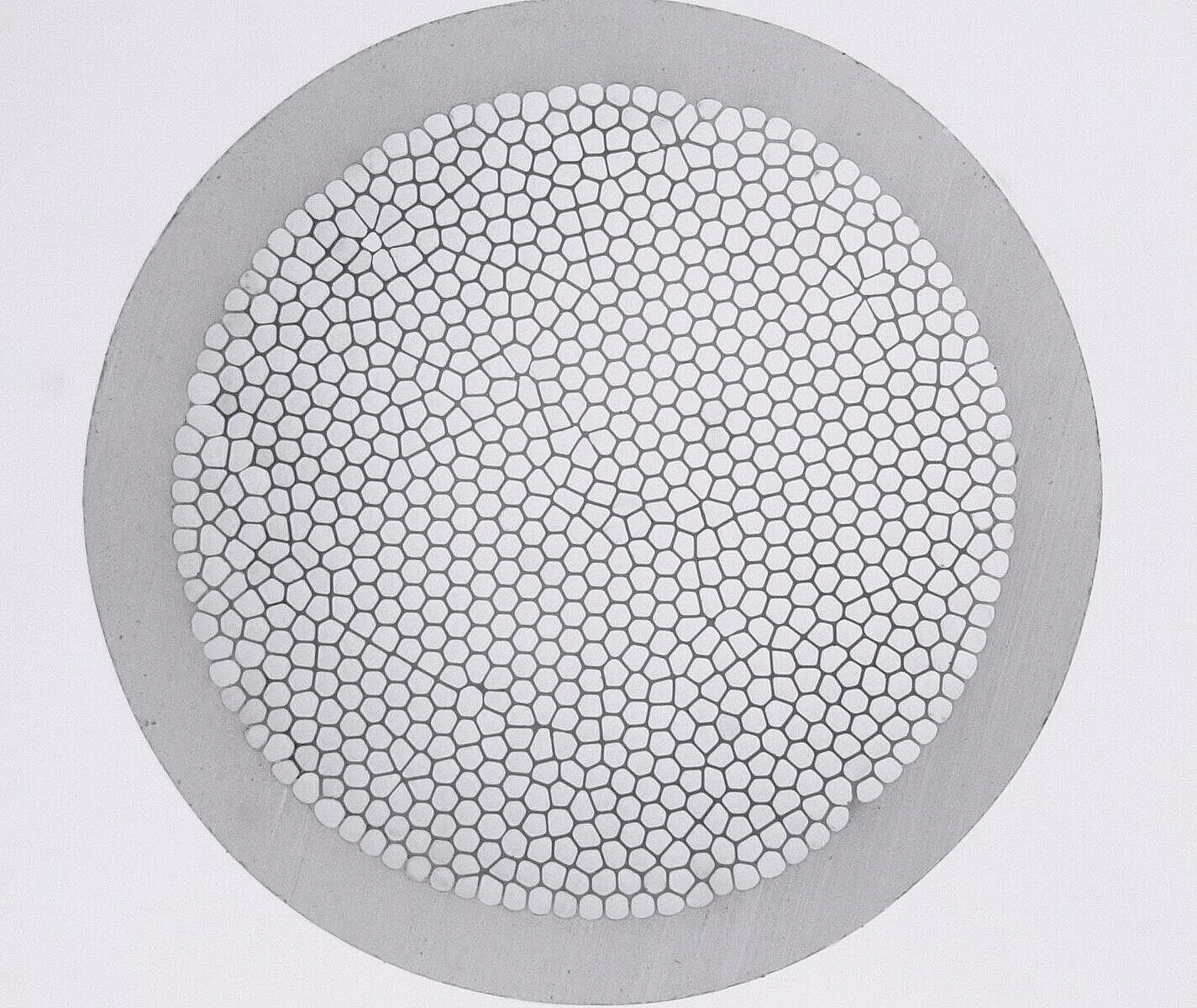

Over 1000 cavities

A capillary with a diameter of 9.5 mm, over 1000 individual cavities, and an average inner diameter of approx. 260 µm.

The multi-capillary impresses with its size and number of channels, which was achieved through a very high packing density. Due to its extremely thin walls between the individual capillaries, it is lightweight despite the high number of channels.

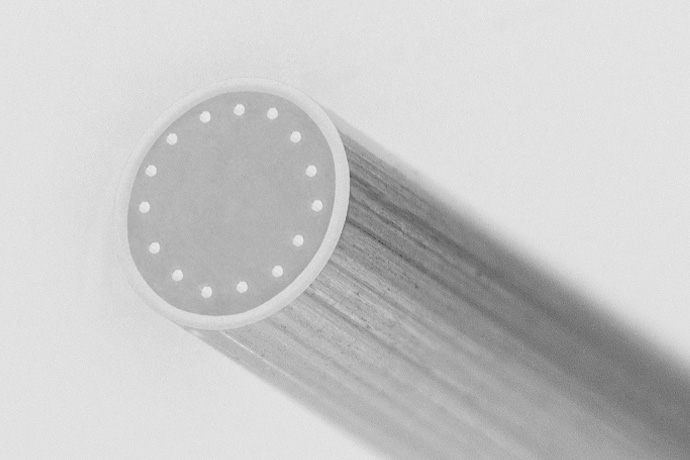

16 in 1 – preform

This preform for the redrawing of glass capillaries was developed on the basis of customer requests and is used for the drawing of fibers with appropriate holes. The preform with 16 channels arranged in a square in a circular cross-section was made of quartz glass and can be drawn out to small capillaries < 1 mm.