Glass nozzles

Our glass nozzles are extremely versatile and have been designed to withstand high pressure. As a larger version of the micropipette, the two share similar characteristics. The glass nozzles have been designed to flexibly adapt to the task at hand. For example, tips can be anything from very short and steep to extra long with an even inner channel. The outer diameter is also your choice: anything between 1.5 mm and 10 mm.

Good connections

The nozzles can be adapted in a number of ways. In addition to the standard plastic Luer connectors for outer diameters from 1 to 2 mm, sealing ridges for Swagelok fittings or customer-specific sealing systems are an option. Particularly fine tips can also be supplied in closed form in order to protect the delicate openings from contamination.

SPECIAL

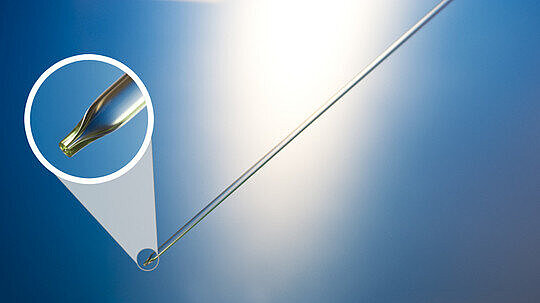

Focusing nozzles

Our customers use thick-walled, long-conical nozzles to concentrate ionized gases accurately on a point under high pressure. Our aim when designing the nozzles was to create a nozzle that was as long and conical as possible. The nozzles consist of a very thick-walled body, for which the ratio of wall thickness to inner diameter continues to the tip. This enables maximum stability and pressure resistance. The inert glass material permits the concentration of hot gases, without contaminating them through reaction with the nozzle.

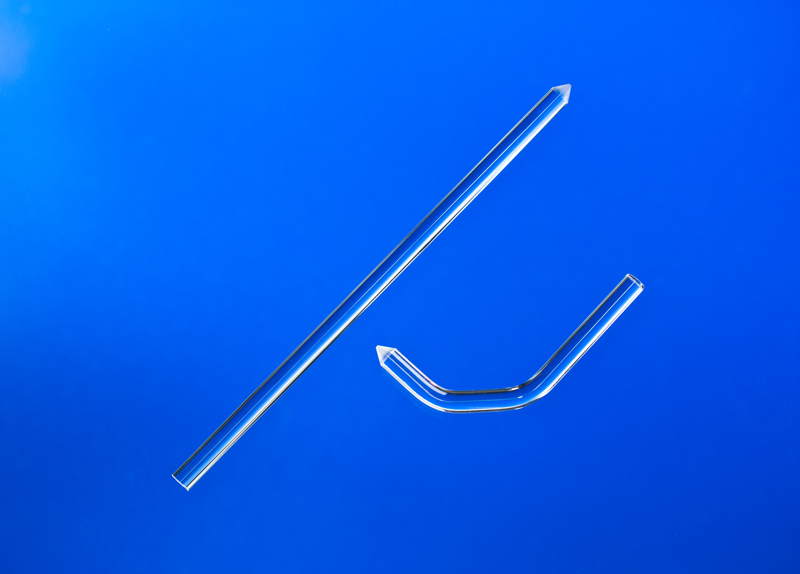

Sampling nozzle made of quartz glass

For the extraction of hot samples from a combustion process or directly from a flame, special nozzles made of quartz glass can be manufactured, which even remain stable at high temperatures over 1000°C. The small internal volume of the capillary serves the extraction of the samples. Especially adjusted to the stream of gas, capillaries with bends can be produced.