Special solutions

Individual products tailored to your requirements are standard practice at Hilgenberg

We don’t just do standard. Quite the opposite, a large number of our customers request individual products that we then produce with the greatest care.

These products are as varied as the applications they are used for. If you are looking for a manufacturer that can make very special glass parts, then you’ve come to the right place!

The examples on this page provide a small insight into the many options available.

Glass bulbs for the light bulb industry

For many applications in industry and medical technology, bulbs are hard to replace with alternative light sources, like LED. The range of colors of the bulbs, in particular, differs from LED lights. Hilgenberg produces different glass bulbs for the manufacturers of light bulbs. Both low-melting soda-lime glass and high-melting aluminosilicate glass are used.

Glass capillary for targeted stimulation of bee antennae

An example of a specific product development. The demand of the customer was to manufacture an easily adjustable double-channel capillary with a defined distance. The capillary was used to study the reaction of bees to a targeted exposure of substances in the air. Here, the two capillaries were aimed specifically at the antennae of a bee. The capillary comprised a solid body for the intake of the module and two flexible feed lines made from coated glass. These could be bent relatively flexibly in order to guarantee an optimal connection.

Sealing glass with high thermal expansion

With its high thermal expansion of 9.9 ∙ 10-6/K-1, as well as its Tk100 of 265 ∙ 108 Ω cm, our glass type 0834 provides the ideal conditions for the thermal expansion of various types of steel, in particular ferritic steels (1.4762, 1.4820 and AISI446) which need a high thermal expansion coefficient. The glass has a wide temperature range of viscosities and can thereby be processed very well.

Light pipe: Getting straight to the point

This part is a component of a scintillator-photomultiplier tube detector for a scanning X-ray microscope. The detector converts X-rays into easily measurable electrical signals. Most scanning X-ray microscopes operate at low to moderate vacuum. The light pipes in those instruments comprise a type of transparent plastic, which can be heated up to 80 °C.

The components in this microscope operate under an ultra-high vacuum (UHV), which means the material is heated to 100 °C. When manufacturing the components, the customer decided on a glass that is both highly temperature-resistant and UHV-compatible. Other requirements, concerning the internal reflections in the pipe, could also be achieved using glass.

Voltage at a short distance: Luggin capillaries

A Luggin capillary is a special tube which is very important for any measurements under current flow. When measuring a voltage, a drop in voltage occurs due to the distance from the working electrode. In order to keep the distance as short as possible, the reference electrode is linked to the electrolytes via a Luggin capillary.

This specific customer application involves the electrochemical storage of energy in a battery. A special feature of the capillary is the membrane at the end of the capillary, as well as the three connectors for the feed of the electrolytes.

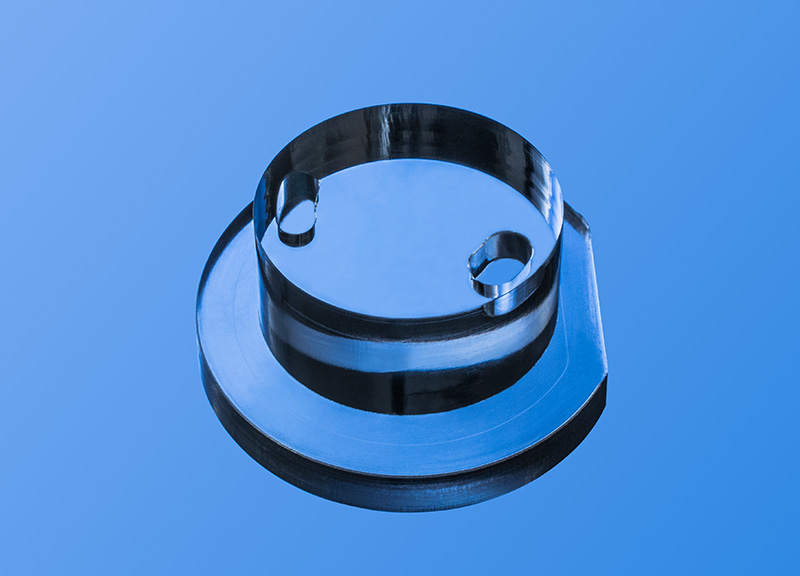

Complex component made of quartz glass

This is an optically active, mechanical part made of quartz glass. It is used for fixing work pieces. The component needs to be highly transparent so that the workpiece can be processed using radiation. The blind holes in the plane surface, which are completely polished, present a special challenge.

Glass capillary with side-mounted connectors

This component for a laser application consists of a solid glass body with a large, central 500 µm hole, which can be subjected to an additional stream of gas via three side-mounted connectors. The connectors are UV-adhered in lowerings and come into contact with the capillary vertically. The central capillary is used to stimulate the process gas with a laser. This component is just one example of the possibilities of our capillary production, as well as the grinding and joining technology.

Carpules with special-rolled rim

Here is an example of adapted standard products from the prototype and pre-series development. The task was to produce a carpule that differed from the industrial standard with a smaller rolled rim and a far shorter length. A sample production with traditional carpule machines would have been too expensive. So the more economic option of semiautomatic production was chosen to produce the prototypes in a short period of time and at an acceptable cost.

Laser sublimation-drilling in flat capillaries

When it comes to drilling small holes in thin walls, conventional drilling reaches its limits. This is why we use laser drilling. Here, a rounded cutting edge is created from the vaporization of the glass, improving the resistance of the drill hole. Shown here, small holes with a diameter of less than 1 mm have been drilled into the sidewalls of a flat capillary.

2D-surface patterning

Especially for the surface patterning of borosilicate and quartz glass, Hilgenberg has implemented a laser-based process with which 2D structures can be created on the surface of glass substrates in pane, tube and rod form. This means the finest of structures can be created. Among other things, the process is used to apply marks, scales and reference points to glass. Letterings and logos are also possible, as well as 2D barcodes.

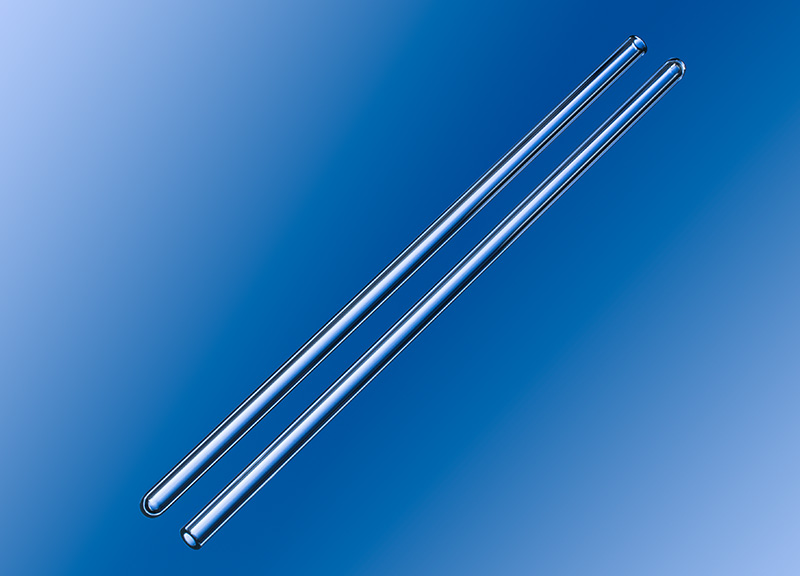

High-precision test mandrels made of different materials

We manufacture high-precision test mandrels from a variety of glass types especially for the 100% stent check. The special processing of the test mandrels means they have a frosted light-refracting surface, which is resistant and can be precisely adjusted to the geometry of the stents. Different solutions in the range of 0.5 to 40 mm are possible.

Measuring ampoules with conical bottom

In addition to standard round and flat bottoms, we also manufacture conical bottom shapes. These are particularly useful when valuable samples need to be completely removed from the tube with a tip. The sample collects in the middle of the cone, out of which you can take the smallest of sample quantities.

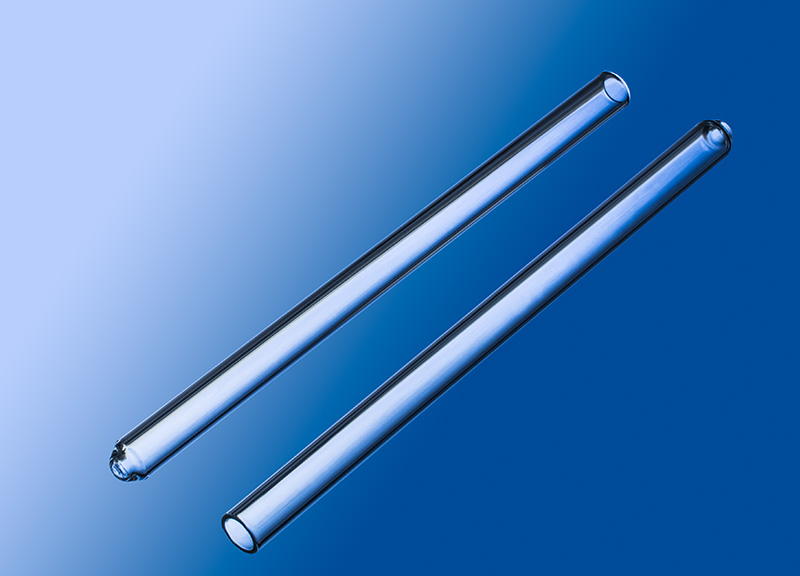

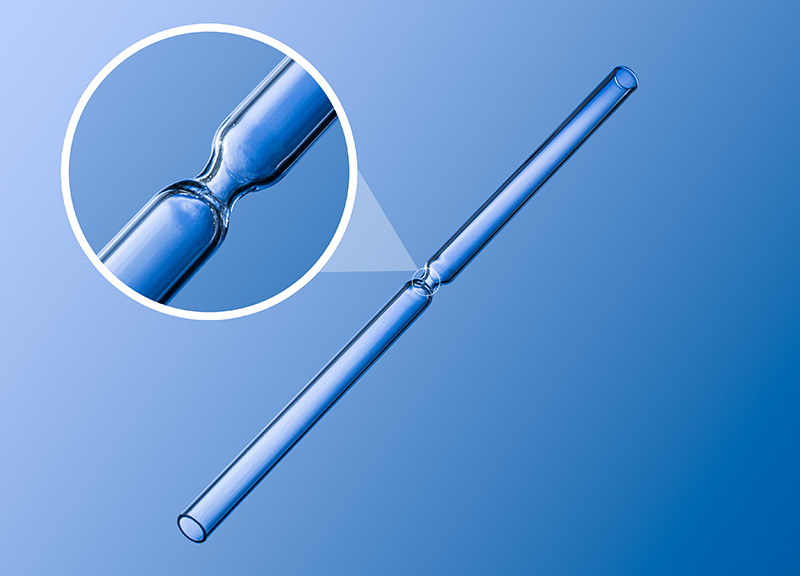

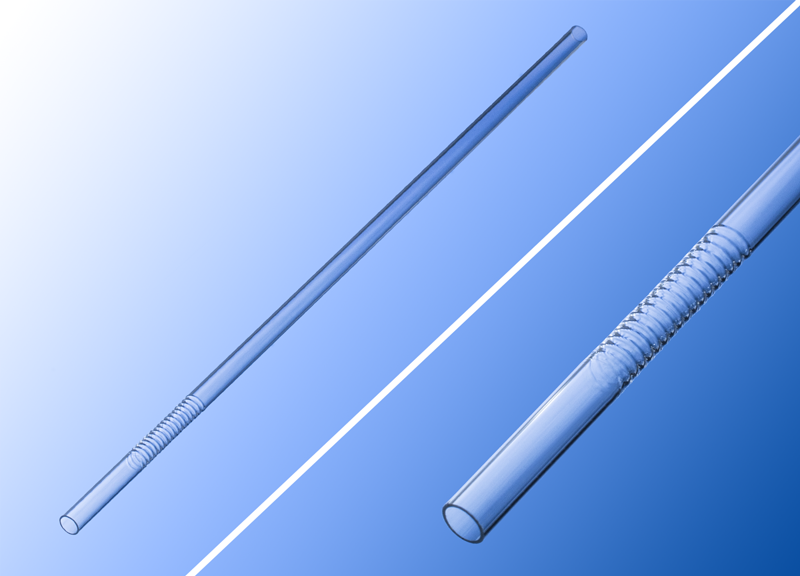

Glass tubes and glass capillaries with targeted constriction

We manufacture glass tubes and glass capillaries with targeted constrictions of the diameter. This cross-section constriction enables the realization of various applications, such as a reduction of the flow, holding a float such as a bead or, in connection with a filter, the sedimentation of a sample in the tube.

Finely scaled glass cannulas

These glass cannulas are suitable for taking samples of liquids, secretions and gels. With a fine scale of 1 mm or 0.50 mm, at a height of 20 mm from the tip, the scale enables the user to read the filling level of the capillary and to take exact sample quantities. The scale is directly inscribed in the glass surface using a laser and thus resistant to acid and solvents.

Capillaries with graduation

In order to easily read the filling level of capillaries, these capillaries can be marked at a set distance (here 10 mm) with a laser. The marking is made by surface forming and is abrasion-proof and solvent resistant. The interval and quantity of marks is freely selectable.

Glass capillaries with grip

Using a laser, the surface of these glass capillaries has been partially reformed to create a grip. The grip circulates the entire circumference of the capillary at a height of 10 mm. The example shows a gripper automatically picking up the capillaries on a dispensing robot. You can freely choose the thickness and the length of the structuring.

Capillaries with fused frit

The melting of small glass frits in capillaries is a particularly challenging task. However, this is possible using our laser processing technology and ensures minimum damage to the frit. The heat is absorbed by the glass wall very locally and has a slow impact on the frit. The frit itself remains unaffected by the increasing temperature.

Micropipettes with chromed surface

The outer surface of these micropipettes has been fully chromed in order to create a closed, abrasion-proof and light-blocking surface. They are used for performing tiny repairs with UV-curing substances and adhesives. The chromed surface also permits the use of electrical properties.

Glass tube with side-opening drilled by laser

These glass tubes made of quartz glass have been opened through the side wall by laser drilling. The opening in the side wall can be used as a crossing, for example, where liquid or gaseous media can be injected in the tube or a sensor can be implemented in the channel. We will be more than happy to provide a solution for your individual application!

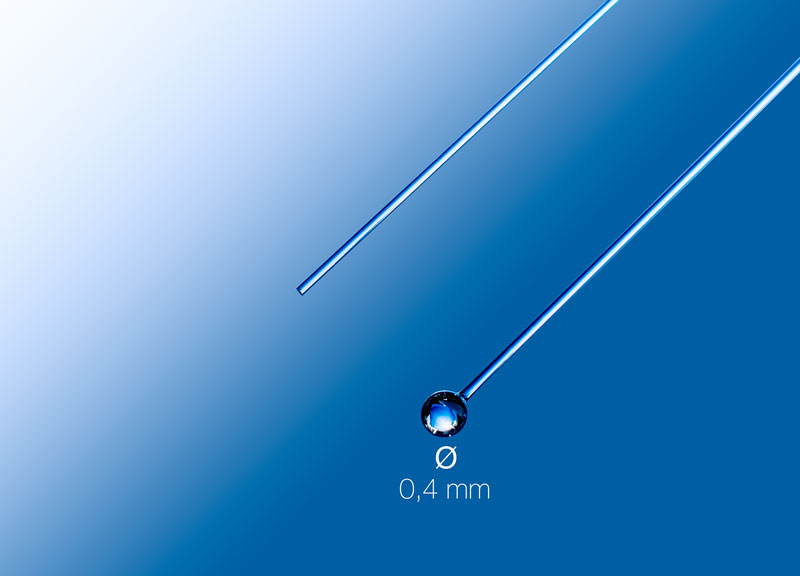

Glass fibers with sphere formed end

Small glass fibers with a diameter from 100 µm can be manufactured with a sphere formed end. Depending on the diameter of the fiber, the size of sphere formed end can be two or even four times larger than the diameter of the fiber.

The fibers are used as sensing devices, as well as optical fibers in lighting technology and microscopy. Made of quartz glass, the fibers are suitable for thermal applications.

Test tubes and packing tubes with sagging at the bottom

Thanks to a new production process, we are able to shape the bottom of various ampoules, test tubes and packing tubes to negative form. This means components such as magnets or identification markers such as 2D barcodes can be worked into the glass without extending over the bottom.

Glass capillaries with expanded internal channel

A specialized product that was developed for installing ignition elements and insulating them from the environment. Expansion of the inner diameter is also possible with longer components. For embedding other components, special gas-proof and water-proof adhesives are available, which also retain their properties at high temperatures.